Einstieg

Film Coaters for the

pharmaceutical industry

Film Coaters – BFC

Pharmaceutical film coating, i.e. coating of particles, is a crucial process in pharmaceutical production. All tablet coating processes are based on three steps:

- Spraying

- Blending

- Drying

Tablets are mainly coated to achieve a modification of substance release, protect the substance against light and moisture or to cover the bitter flavor of the tablet formula. Compatibility of the dosage form is relevant as well. Coated tablets are easier to swallow and can be better distinguished due to different colors. Processing active ingredients in tablet coating, the active ingredient coating, is becoming more and more relevant.

Text

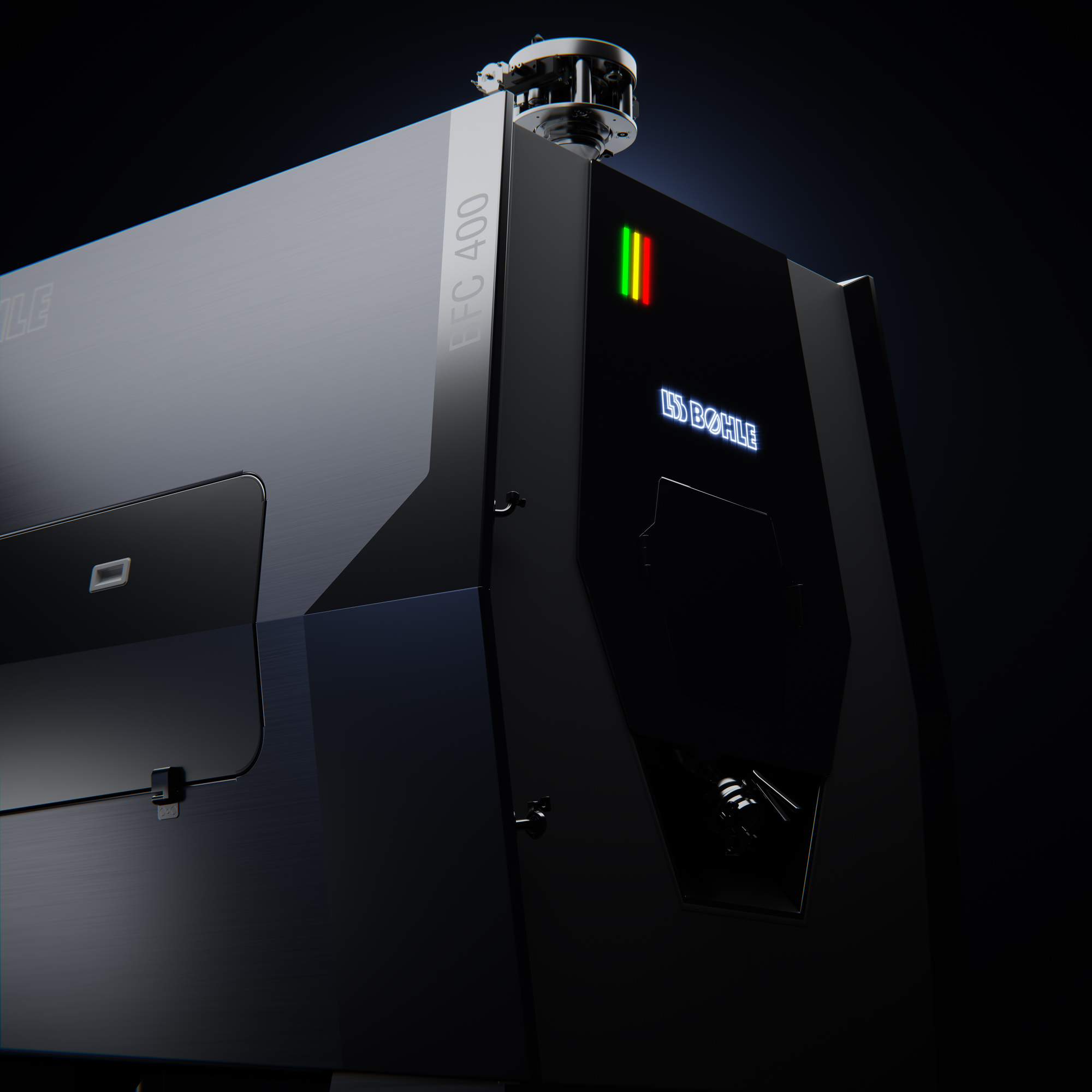

Coating with the L.B. Bohle Film Coater

L.B. Bohle has been the technology leader in the development and production of film coating systems for the pharmaceutical industry. The Bohle BFC Film Coater is the high-end version of the L.B. Bohle coaters, standing out with high efficiency, optimized output, and lowest suspension loss.

L.B. Bohle film coating technology is based on three essential and unique properties:

- The drum geometry

- The patented twin spirals

- The air system

Best process management

All L.B. Bohle coaters guarantee best-of-class product processing and excellent cost effectiveness. The flat tablet bed in a long drum geometry, as well as continuous adjustment of the inclination angle ensure optimal movement of the cores. The systematic compulsory guide in the drum enables continuous product movement. There is no tablet twinning, Both solid and paint losses are kept low.

Lowest suspension losses

Innovative concepts for processes, as well as for cleaning, improve the tablet coater functionality and deliver outstanding results. The type of air system reveals significant process-related advantages. The risk of spray-drying at the suspension is a thing of the past. This reduces spray losses and improves coating structure.

Tablets are handled more carefully thanks to the pan geometry and the blending and conveyor elements. Through change of direction of pan rotation, tablets can be discharged completely and without containments.

Trennbild

Vorteile

Benefits of the Film Coater

| Patented helical baffles | |

| Mixing at two levels using counter-rotation | |

| Large spray surface, length: Diameter >1 | |

| Prevention of spray-drying, heating only in tablet bed | |

| CIP-cleaning |

| Guaranteed scale-up | |

| Better performancer by up to 40% | |

| Best uniformity: RSD < 2% | |

| Lowest spray losses < 5% |

Our product brochure for coating with the BFC Film Coater is available for download here:

Technische Merkmale

Variations and

Technical Features

We offer our Film Coaters in different sizes and technical designs.

Our product brochure for coating with the BFC Film Coater is available for download here:

The following list provides an initial overview and comparison of our various film coaters for your tablet coating. We look forward to your request for detailed information.

| BFC 100 | BFC 200 | BFC 400 | BFC 600 | |

|---|---|---|---|---|

| Batch size (brim volume) (L) | 50 – 160 | 100 – 300 | 200 – 650 | 400 – 980 |

| Nozzles | 5 | 6 | 8 | 10 |

| Suspension unit | All nozzles are fed by one peristaltic pump head | All nozzles are fed by one peristaltic pump head | All nozzles are fed by one peristaltic pump head | All nozzles are fed by one peristaltic pump head |

Whitepaper

L.B. Bohle: Leader in Tablet Coating Technology

L.B. Bohle is a leader in tablet coating technology, offering state-of-the-art systems such as the Bohle Film Coater (BFC) and the Bohle Tablet Coater (BTC). These coaters ensure excellent coating results, reduced process times by up to 35% and minimal spray losses. With advanced technology and easy cleaning, they significantly optimize production processes in the pharmaceutical industry.

Download now

Bildergalerie

Ansprechpartner

Your contact for the Film Coater

Burkhard Schmidt

Sales Director

inquiry@lbbohle.de

+49 2524 – 93 23 0