Einstieg

Lifting Columns for the

Pharmaceutical Industry

Lifting Columns – HS

Our goal: Perfect handling for your efficient production process. Lifting columns (HS) have been indispensable for decades in pharmaceutical, food and chemical production.

For example, lifting columns are used for charging process machines such as tablet presses or coaters or in complex manufacturing lines.

Text

Handling with the Lifting Columns

by L.B. Bohle

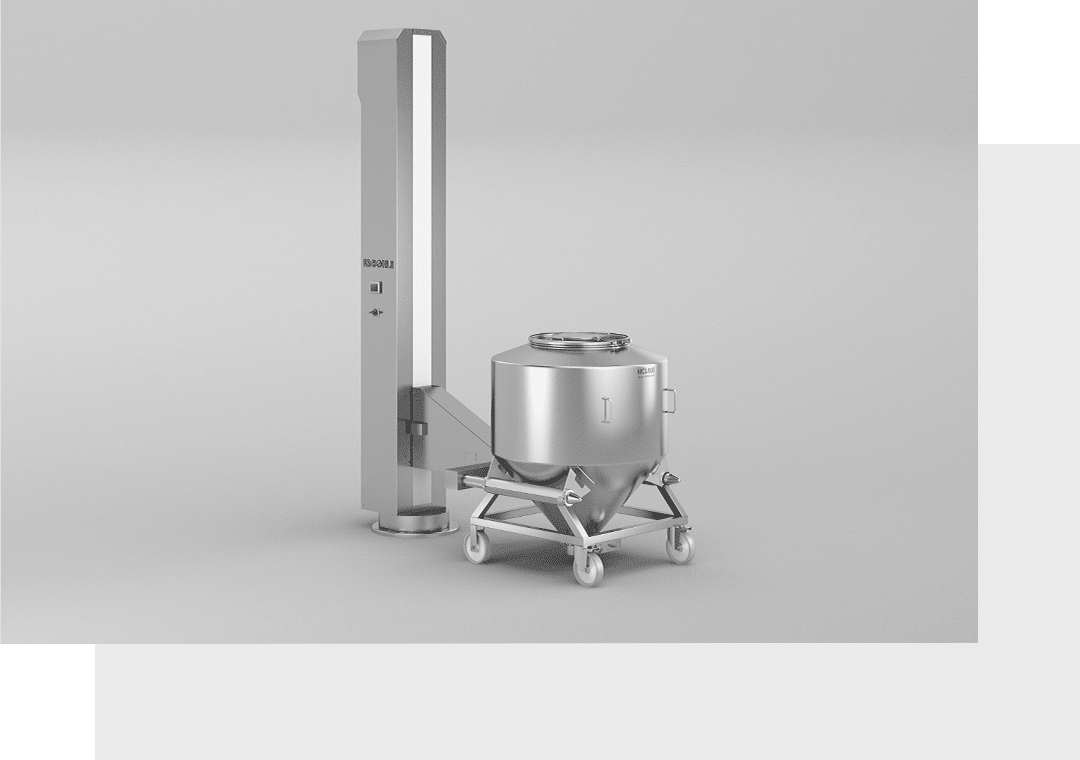

The HS pharmaceutical lifting column is a stationary and space-saving lifting unit for various applications in the pharmaceutical, food and chemical production.

Many years of experience in the area of handling technology have led to continuous further development of the HS lifting column, standardisation and adjustment to the specific requirements in the industries.

Electrically Operated Chain Drives

In contrast to competitors who use hydraulic lifting technology, L.B. Bohle has been relying very successfully on robust and electrically operated chain drives for years. These chain drives require less maintenance than hydraulic drives and users have no hygiene problems in clean rooms.

L.B. Bohle lifting columns are used worldwide for simple as well as complex work processes.

The integration possibilities of the lifting columns in complex production lines are varied:

- Transport of containers on horizontal and vertical levels

- Filling/discharge processes at process machines, such as

tablet coaters, tablet presses, capsule filling machines or sieving - Integration in weighing systems

- Equipment of the lifting columns with containment flaps

for dust-free work processes - Expansion of the lifting columns with cleaning aggregates

Text 2

Space-Saving

Lifting Column SL

Since capacity is usually limited in production rooms, space-saving lifting columns are paramount. Production systems

with their auxiliary units often take up a lot of space, making the integration of a lifting column difficult.

L.B. Bohle meets the requirements regarding reduced space for lifting columns by preseting the SL type lifting column. The HS 1000 SL lifting column, with its already integrated control cabinet, requires only 0.3 m2 of space and can therefore be used even in very limited spaces.

Just like the standard lifting column, the HS SL stands out with its robust construction and the electromechanical lifting drive.

Control via touch panel

The lifting column HS SL is operated via a touch control based on microcontrollers. The lifting column is controlled automatically by an intuitive user interface.

Available variations of the HS SL

| HS SL 1000 | |

| HS SL 1500 | |

| HS SL 2000 |

Trenner

Vorteile

Benefits of the Lifting Columns

| Standardised, space-saving design by integrating electrical and mechanical components within the lifting column | |

| Ergonomic and GMP-compliant design facilitates cleaning and operation | |

| Precise positioning of containers at various heights and positions |

| Automated and semi-automated process sequences through the use of a PLC with touch-panel visualisation | |

| High flexibility through optional equipment and individual solution variants |

Our product brochure for the HS SL lifting column is available for download here:

Technische Merkmale

Variations and

Technical Features

We offer our lifting columns in different sizes and technical designs.

Our product brochure for the HS SL lifting column is available for download here:

The following list provides an initial overview and comparison of our standard lifting columns.

We look forward to your request for detailed information.

| HS 300 | HS 400 | HS 600 | HS 800 | HS 1000 | HS 1500 | HS 2000 | |

|---|---|---|---|---|---|---|---|

| Max. load [kg] | 300 | 400 | 600 | 800 | 1000 | 1500 | 2000 |

| Standard height [mm] | 2900 | 3400 | 3400 | 3400 | 3400 | 3900 | 3900 |

Bildergalerie

Ansprechpartner

Your contact for the

Lifting Columns

Valeri Raiswich

Area Sales Manager

inquiry@lbbohle.de

+49 2524 – 93 23 0