Einstieg

Fluidized Bed System for the Pharmaceutical Industry

Fluidized Bed Granulator & Fluidized Bed Dryer – BFS

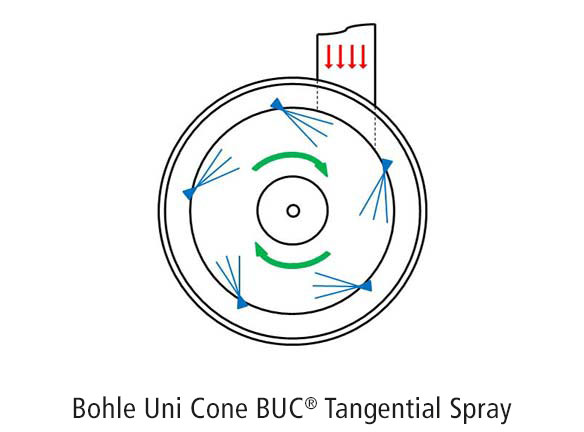

Fluidized bed systems have been used in the pharmaceutical industry for many decades. Adding an aqueous or alcoholic granulation medium compresses the mixture of dry powder particles. The fluid contains a volatile solvent which can be removed by drying. For a long time, fluidized bed solutions were dominated by top-spray. However, the benefits of systems with tangential spray nozzles have become more apparent, thus tending to take over top-spray granulators. L.B. Bohle’s fluid bed granulation portfolio includes R&D systems for small production volumes as well as production scale systems.

Text

Granulation with the

Bohle Fluid Bed Granulator

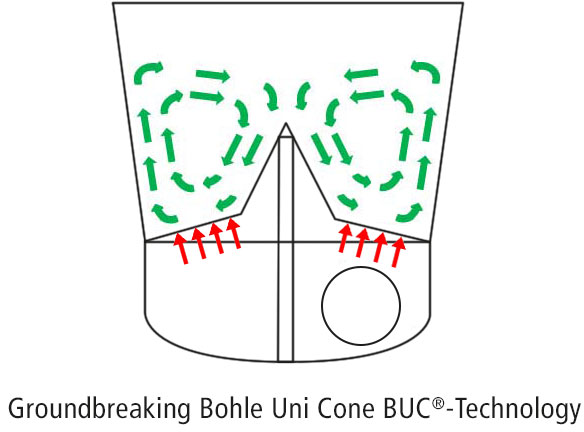

L.B. Bohle uses the Bohle Uni Cone BUC® process to optimize fluidized bed

The patented Bohle Uni Cone BUC® is a specially slotted air distributor plate with a conical displacement cone. This design allows for a complete fluidization of the particles. This tangential particle motion achieves a uniform film, e.g. on pellets, without any twins.

Since the fluidized particles or granules move tangentially at relatively low fluidization height, they do not require a high-volume expansion. This reduces the required installation height, saving costs and production floor space.

At least six filter elements of the BFS, that can be cleaned separately, ensure that the air flow though the product bed is uninterrupted.

Drying, granulation and coating without need for alteration

Another advantage of the tangential design in facilities from L.B. Bohle is that granulation, coating and drying can be carried out in a single system without having to reconfigure the equipment.

For the drying process, the BFS fluidized bed system can be equipped with an online moisture measurement system using NIR technology (similar to infra-red analysis). This innovation makes it possible to identify the current moisture level, precisely and reproducibly, during the granulation and drying process.

Vergleich

Comparison of Fluidized Bed Equipment

Benefits Bohle Uni Cone BUC®

| Effective air distribution: Quite narrow particle size distribution and formation of spherical granules |

|

| Frameless product bottom plate design: Simple cleaning |

|

| Inspection of air plenum through the back pipe: Avoidance of cross contamination in the bowl inlet |

|

| Filter inspection: Safe location for the operator standing on the floor |

|

| Handling of the bottom plate: Safe de-installation in combination with an in-wall built lifting column |

Trennbild

Vorteile

Benefits of the Fluid Bed Granulator

| Complete fluidization of particles | |

| Even film coating, no twin formation | |

| Integration of PAT, NIR and WIP | |

| Patented filter cleaning – patented diffuser |

| Lowering of filters via electric drive | |

| Easy-to-remove distributor plate | |

| Low installation height, efficient space utilization | |

| Pressure surge resistance up to 12 bar- optimum conditions for containment applications |

Our product brochure for granulation with the fluidized bed system is available for download here:

Technische Merkmale

Variations and

Technical Features

We offer our fluidized bed systems in different sizes and technical designs.

The following list provides an initial overview and comparison of our various fluidized bed systems for your granulation. Our product brochure for granulation with the fluidized bed system is available for download here:

We look forward to your request for detailed information.

| BFS series | Qty. of product filter bags | Height of the fluidized bed system [mm] | Number of nozzles (tangential spray) | Control system |

|---|---|---|---|---|

| BFS 30 | 4 | ca. 1980 | 1 | PLC controlled, Touchpanel operated |

| BFS 60 | 6 | ca. 2930 | 2 | PLC controlled, Touchpanel operated |

| BFS 120 | 6 | ca. 3600 | 3 | PLC controlled, Touchpanel operated |

| BFS 240 | 9 | ca. 3920 | 4 | PLC controlled, Touchpanel operated |

| BFS 360 | 12 | ca. 4570 | 5 | PLC controlled, Touchpanel operated |

| BFS 480 | 10 | ca. 4990 | 6 | PLC controlled, Touchpanel operated |

Whitepaper

L.B. Bohle: Leader in Pharma Granulation Technology

L.B. Bohle provides top-of-the-line granulation solutions such as the VMA single-pot granulator, BFS fluid bed systems, and BRC roller compactors. These technologies offer efficient, safe, and environmentally friendly production processes, perfect for the manufacture of solid dosage forms in the pharmaceutical industry.

Download now

Bildergalerie

Ansprechpartner

Your contact for the Bohle

Fluid Bed Granulator

Joschka Raby

Area Sales Manager

inquiry@lbbohle.de

+49 2524 – 93 23 0