Einstieg

Continuous granulation and drying for the pharmaceutical industry

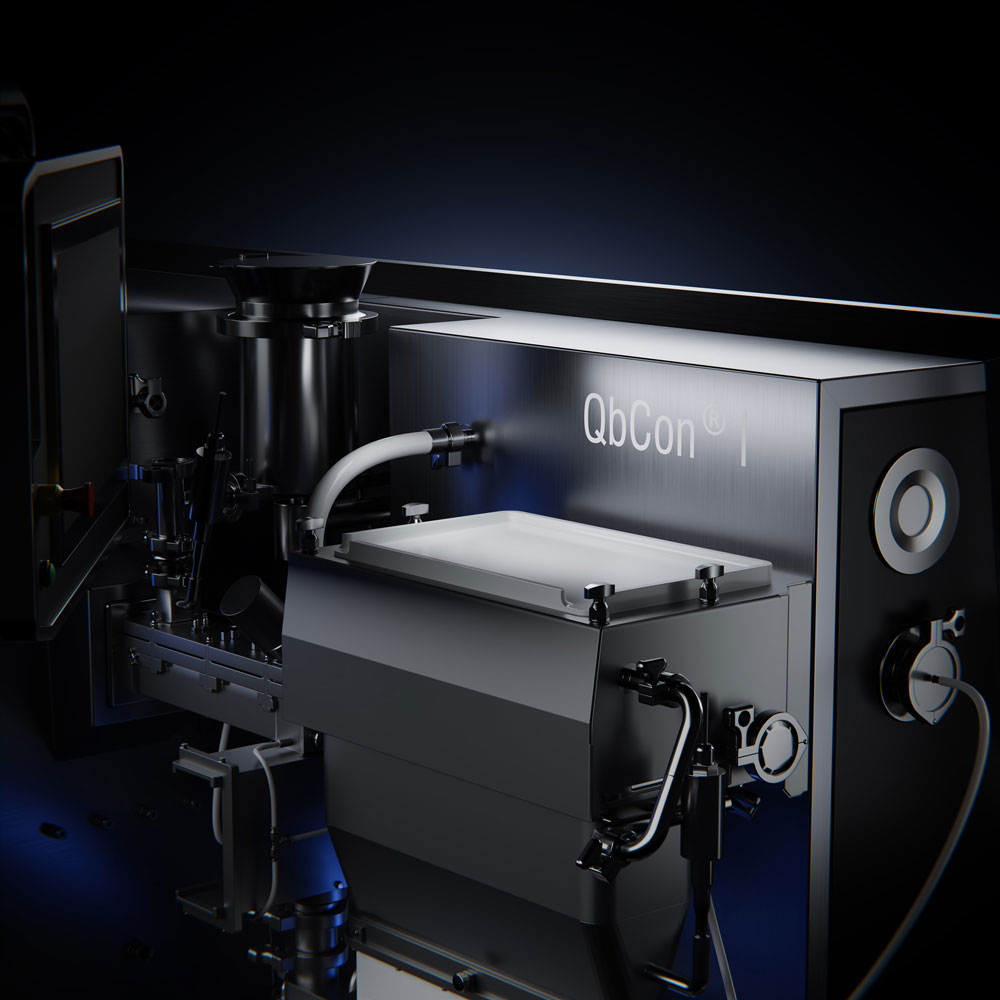

QbCon® 1 – R&D

All developments start in a lab. Continuous processes also require lab-size equipment with small footprints that can handle even very small throughputs.

Continuous wet granulation and drying have been subject to discussion for some time in pharmaceutical research and development (R&D) of oral pharmaceutical solids.

Text

Continuous granulation and drying with QbCon® 1 by L.B. Bohle

Granulation and granule drying also play a major role in continuous manufacturing. QbCon® 1 is the only system for research and development world-wide that meets the quality demands of pharmaceutical manufacture.

First of all, a short residence time of the granules in the dryer with a narrow residence time distribution is essential to be able to remove defective products in a targeted manner without having to discard a large portion of the batch.

Furthermore, narrow residence time distributions simplify the traceability of material in the continuous process, making it easier and less complex to trace finished tablets back to the basic products or to subsequently trace them from the basic products to the finished tablet.

Further important quality requirements for a dryer are

- Even, reproducible drying of all granules – especially of different

sizes – over the entire process duration - A small process chamber to keep the volume in the drying process as low as possible

- And, in particular, a long service life of the exhaust air filters without having to interrupt the drying process or even replace

Thanks to the small footprint, the QbCon® 1 is perfect for the smallest throughputs (nominal throughput: 0.5–2.5 kg/h).

Video

Vorteile

Benefits of the continuous

wet granulator and dryer

| Fully automatic cleaning of the filter during the drying process | |

| Gentle, uniform drying through gentle fluidization and transport | |

| Uniform conveying of the granules from charging to discharge |

| Comfortable handling and easy cleaning | |

| Very short residence time of granules of different sizes | |

| Fast development of new products – secured scale-up |

Our product brochure for the continuous wet granulator and dryer for research and development is available for download here:

Technische Merkmale

Variation and

Technical Features

The following list provides an initial overview for our research and development system.

We look forward to your request for detailed information.

| Dimensions | Approx. 2070 x 920 x 1848 mm |

|---|---|

| Weight | 750 kg |

| Nominal throughput | 0,5 – 2,5 kg |

Whitepaper

L.B. Bohle: Leader in Continuous Manufacturing for the Pharmaceutical Industry

L.B. Bohle is revolutionizing pharmaceutical production with continuous systems like QbCon® 1 and KOCO 25, that enable end-to-end granulation, drying, and coating. These innovative solutions ensure the highest product quality, efficiency, and flexibility with reduced resource consumption, providing an ideal platform for research and development as well as large-scale production.

Download now

Bildergalerie

Ansprechpartner

Your contact for the

Continuous Wet Granulators and Dryers

Burkhard Schmidt

Sales Director

inquiry@lbbohle.de

+49 2524 – 93 23 0